Structural Steel Detailing

Our well experienced structural steel detailing team consists of quality control head, Project managers, team leads and skilled steel detailers, which ensures high-quality work and meet client requirements. Each team member is trained on worldwide standards for steel detailing, including CISC, AISC, British, Euro, and Indian codes of practice.

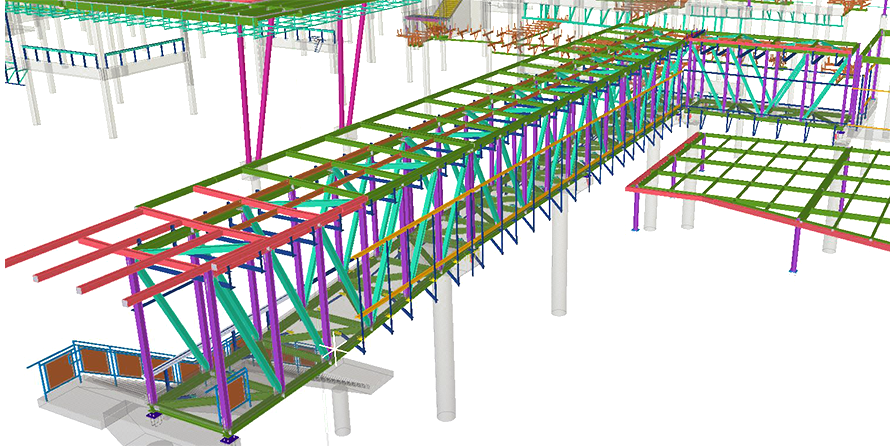

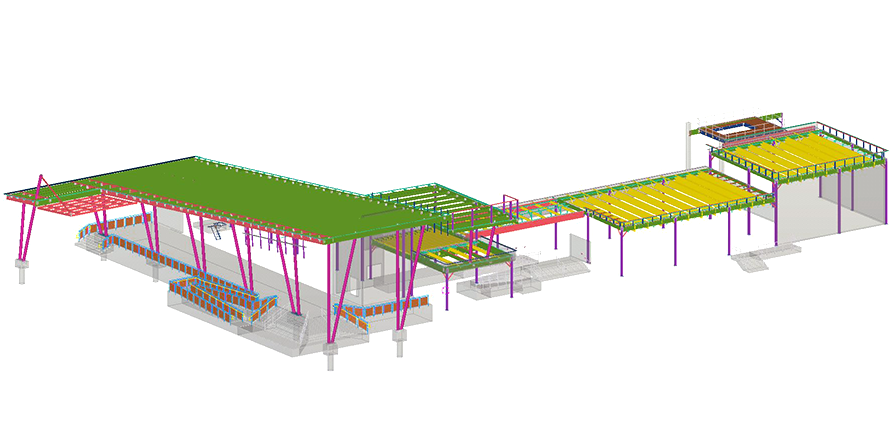

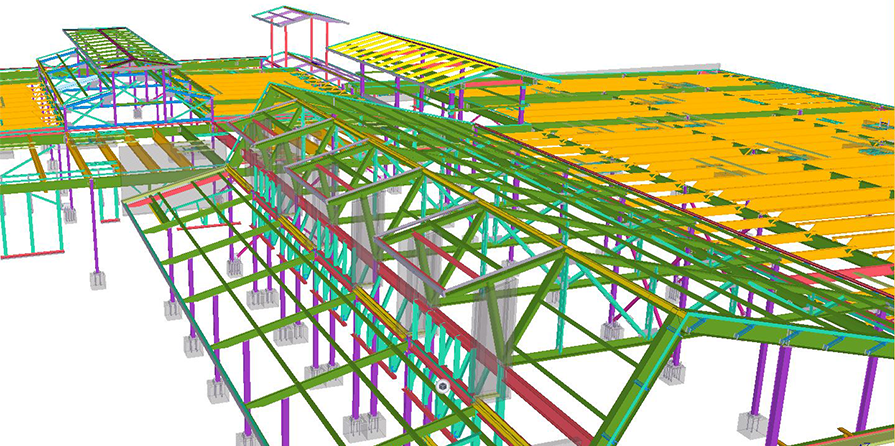

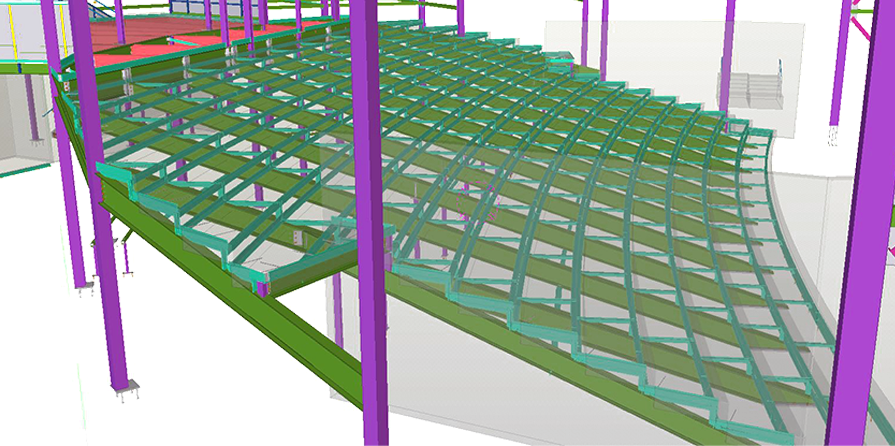

We are proficient in using the latest software tools, including Tekla Structures, Autodesk Revit, AutoCAD, Advance Steel, dynamos and macros. This proficiency allows us to efficiently and accurately create detailed models, drawings, and fabrication documentation. The team is well supported by in-house structural design team - experienced in steel and connection designs, which helps in handling complex projects. We pride ourselves on providing unique solutions that assist engineers in managing designs effectively and enable fabricators to carry out the manufacturing process smoothly. Our expertise and problem-solving approach ensure that intricate and challenging projects are executed successfully.

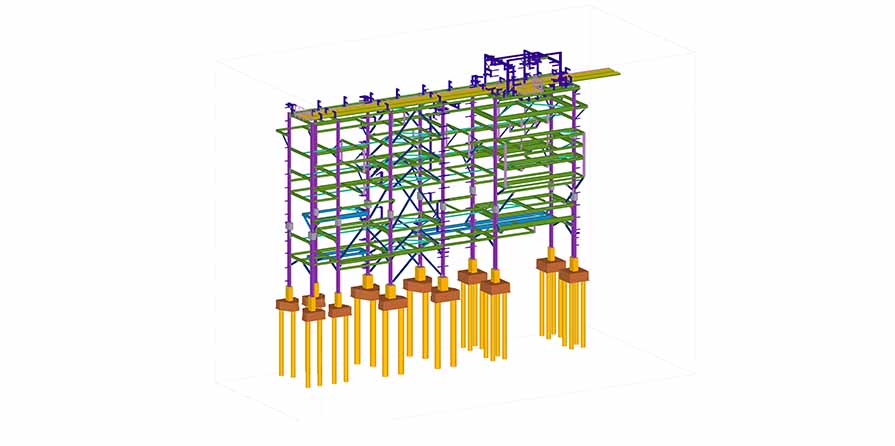

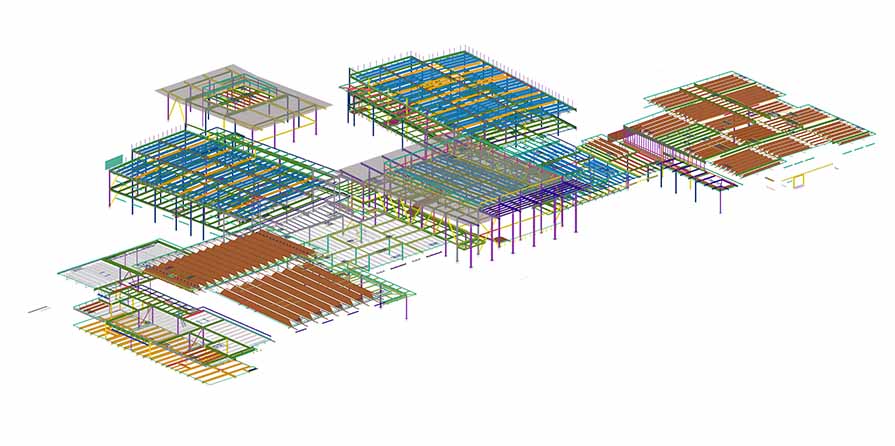

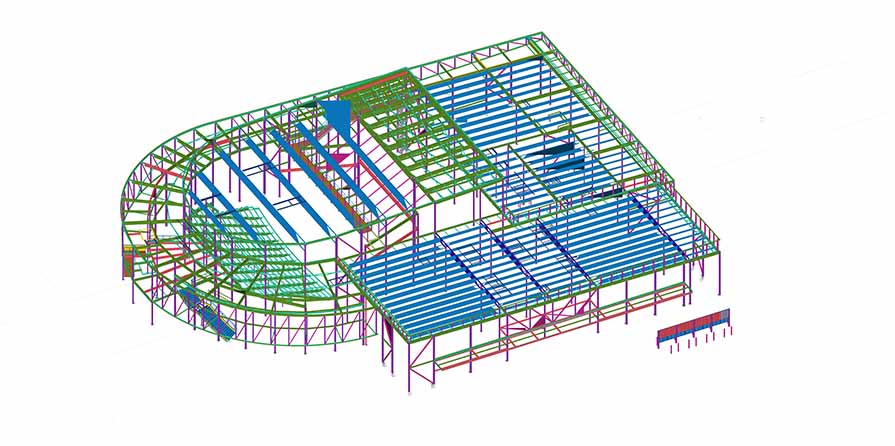

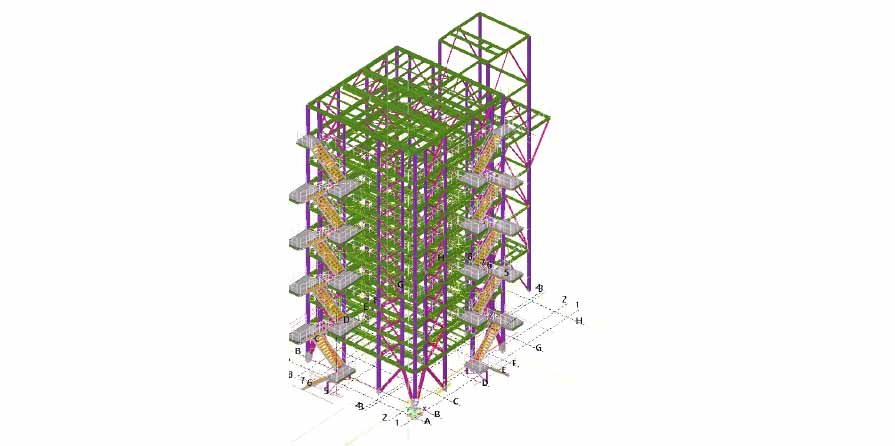

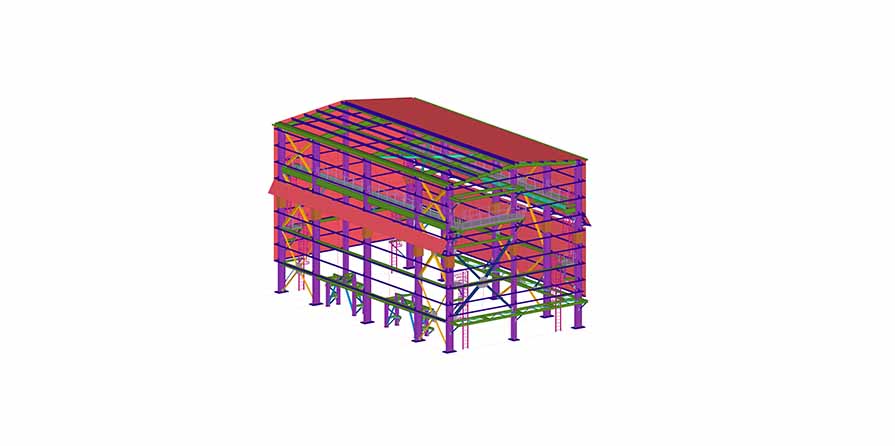

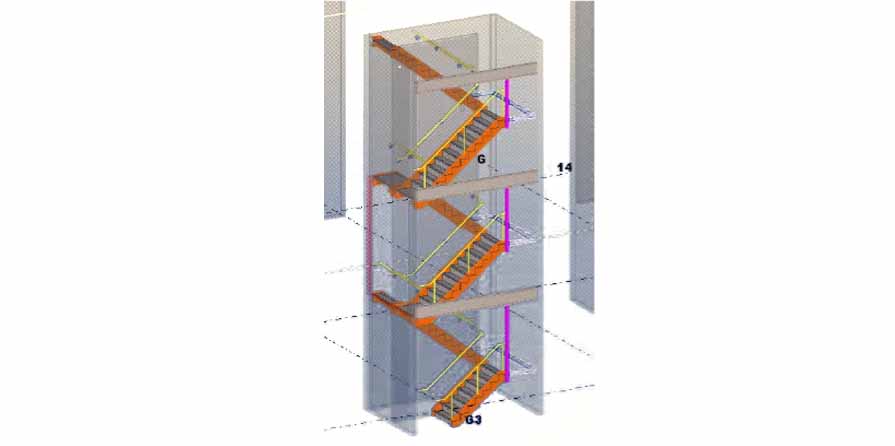

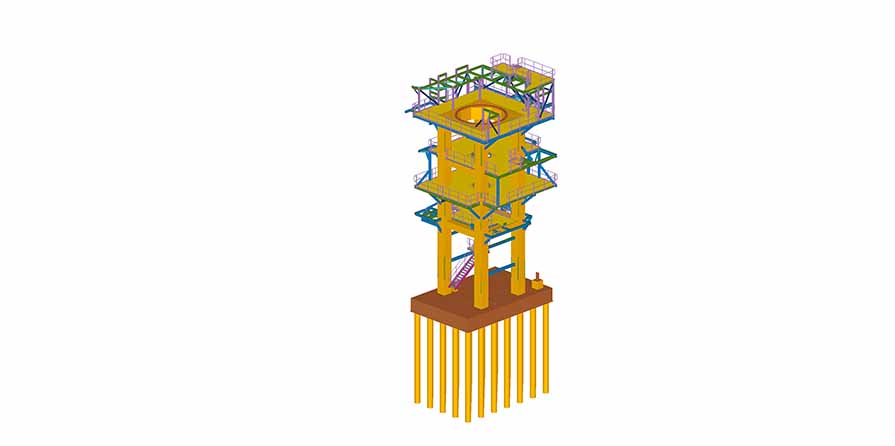

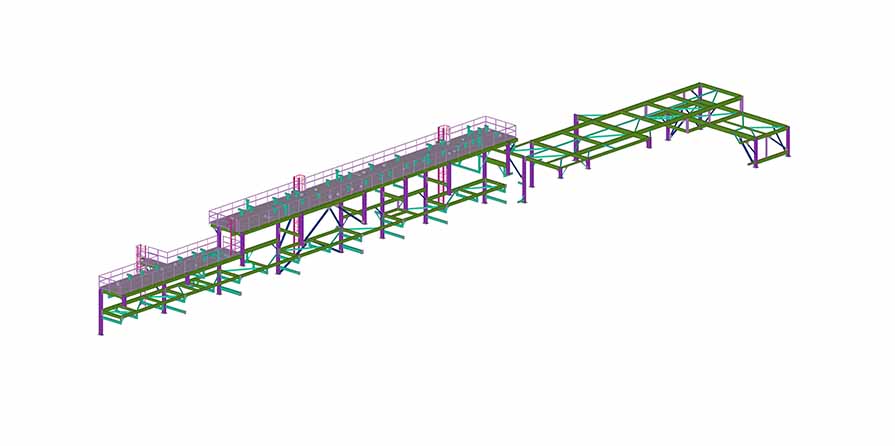

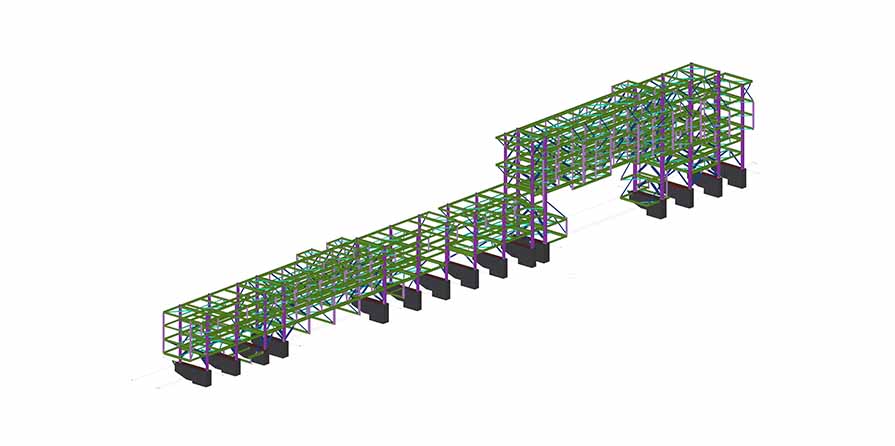

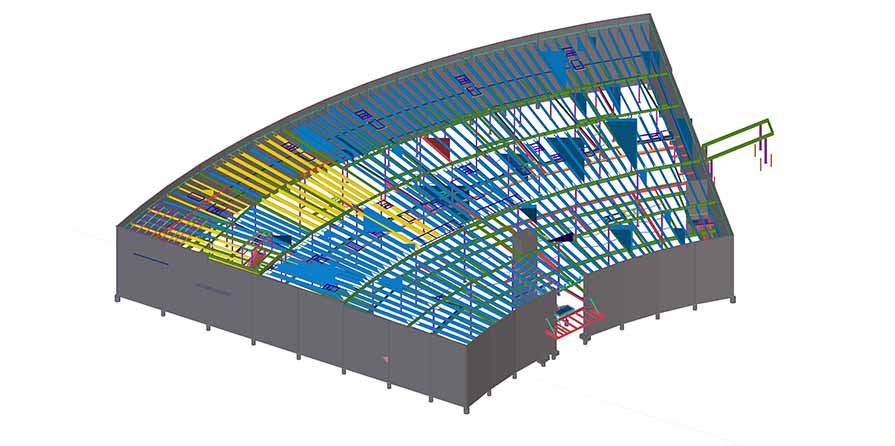

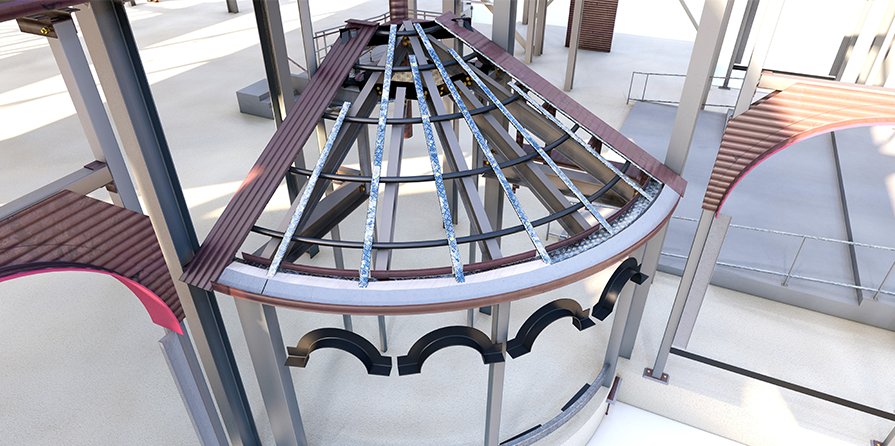

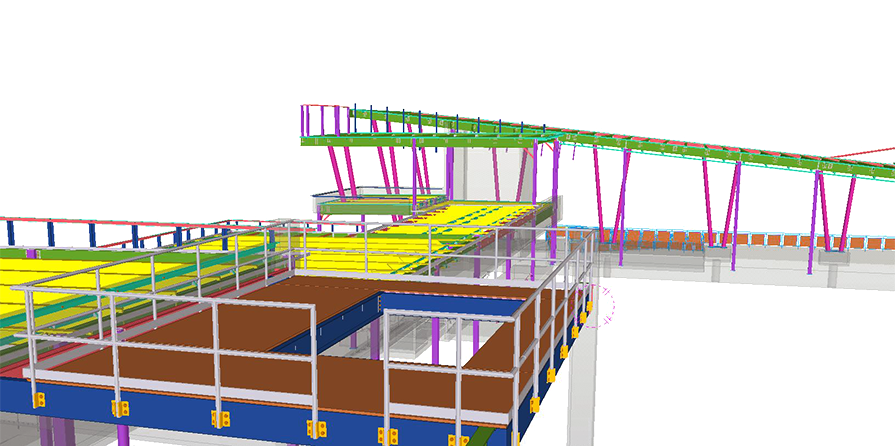

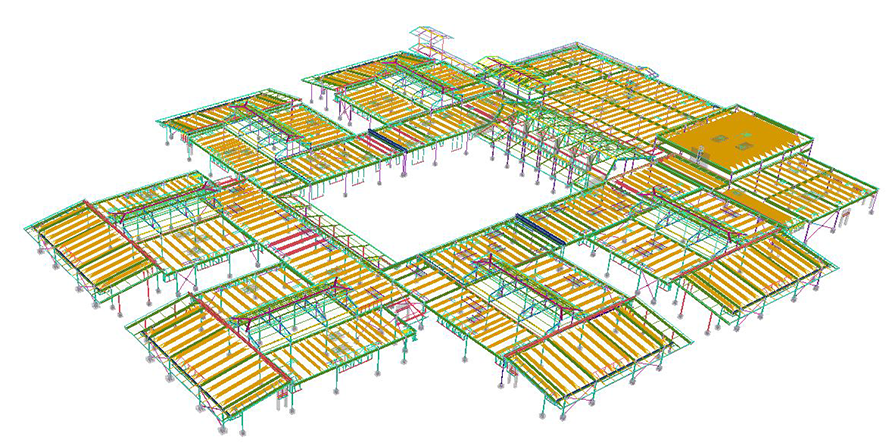

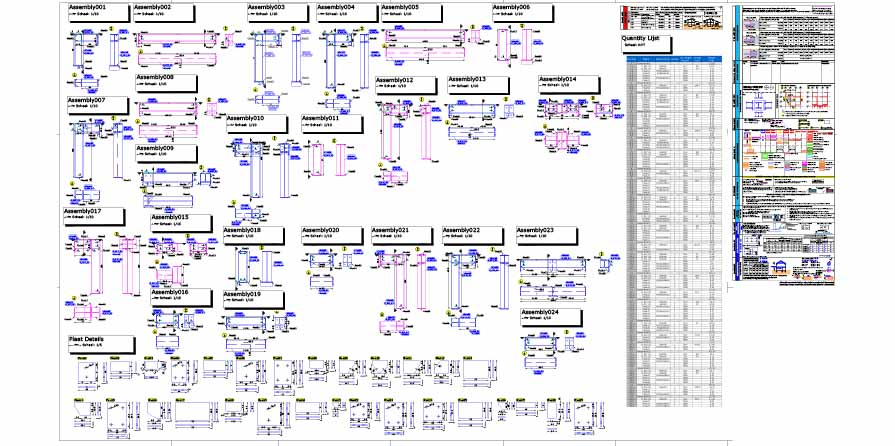

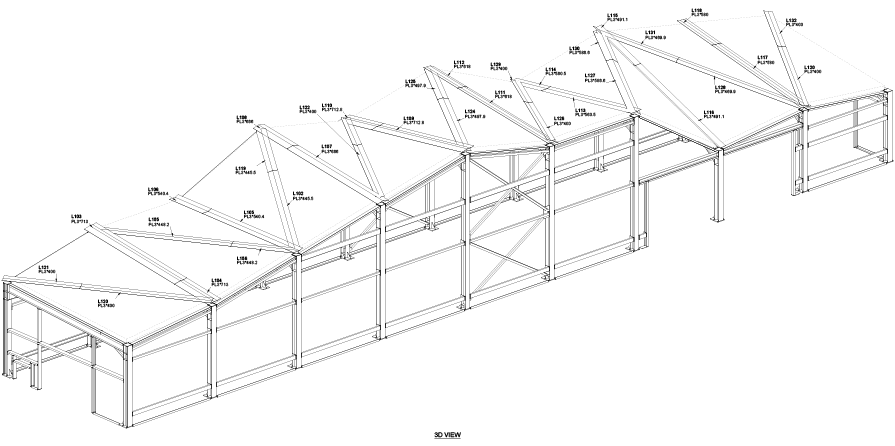

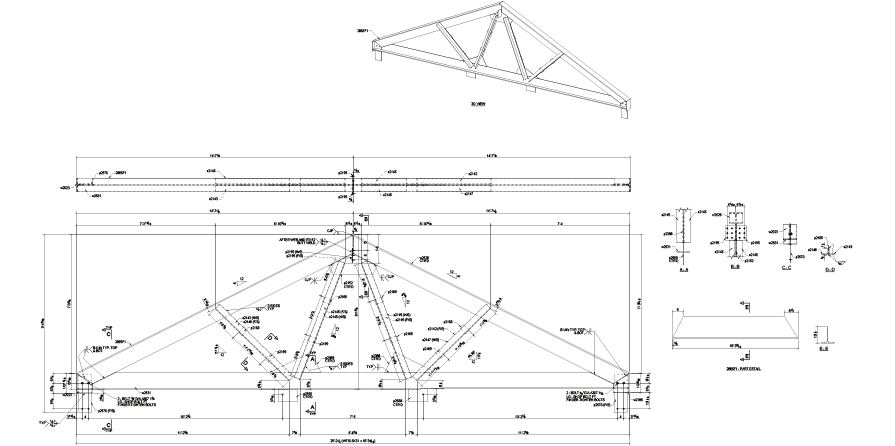

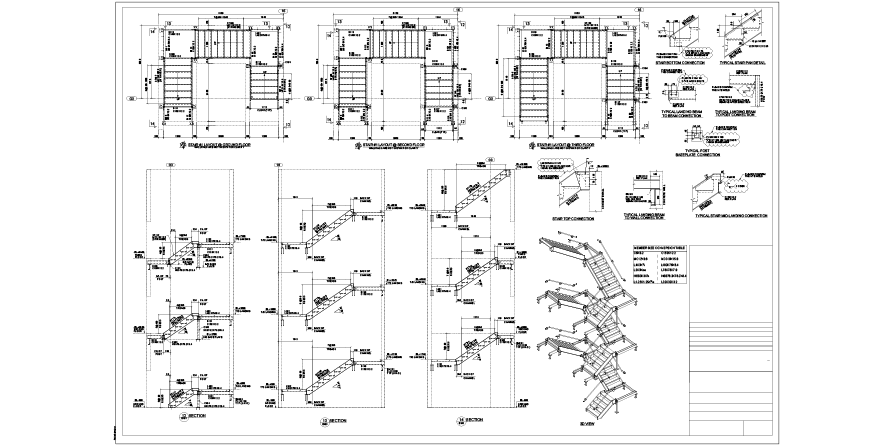

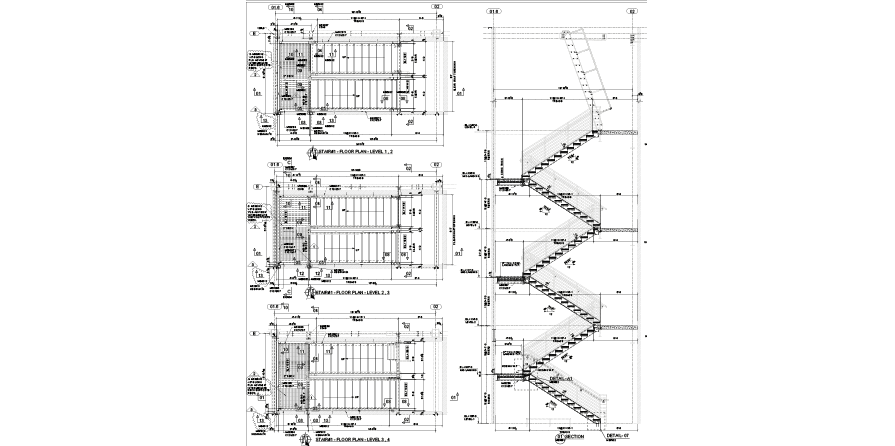

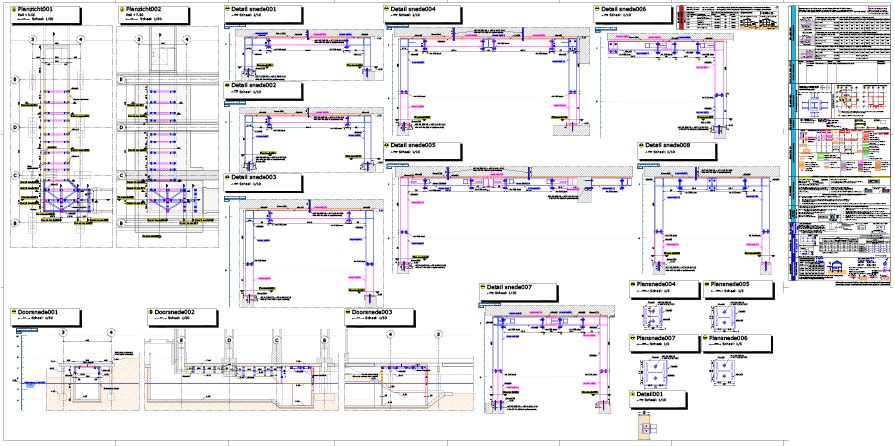

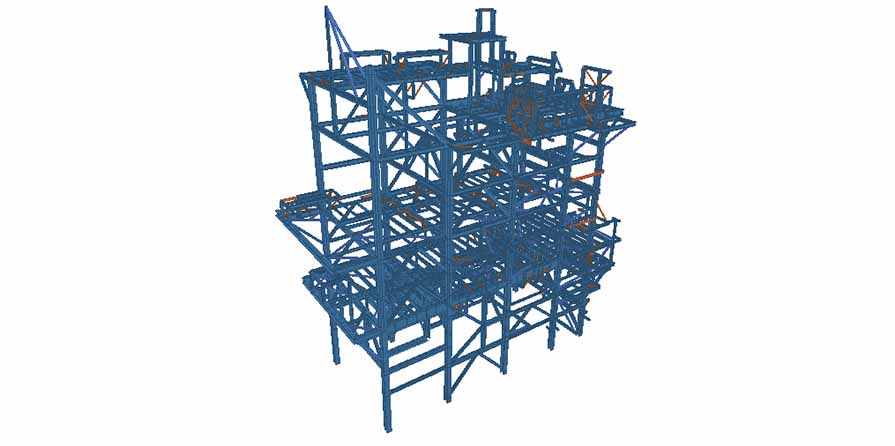

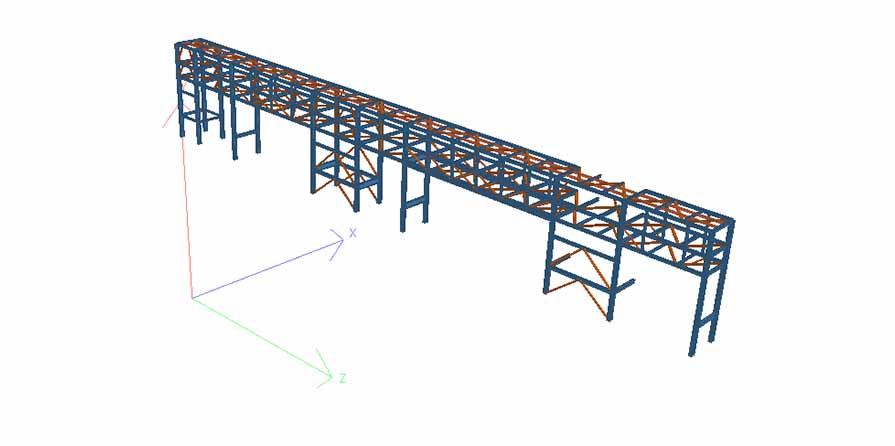

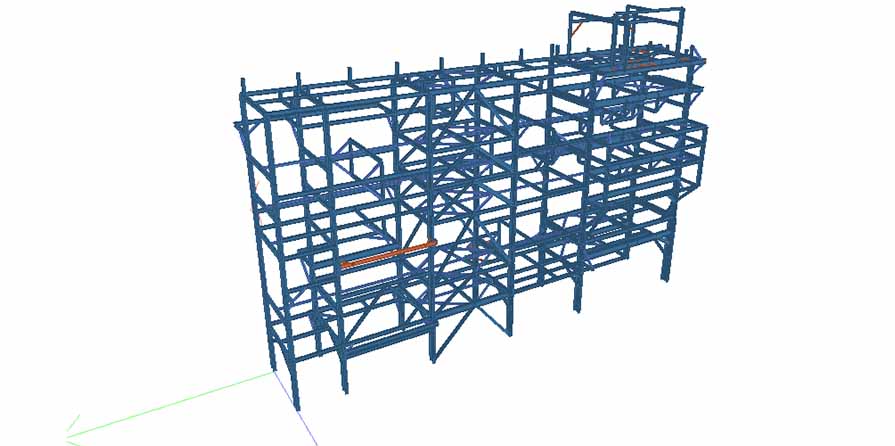

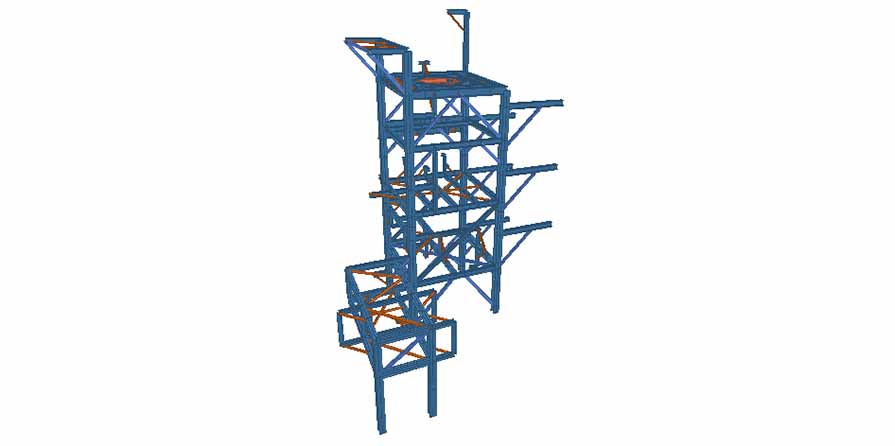

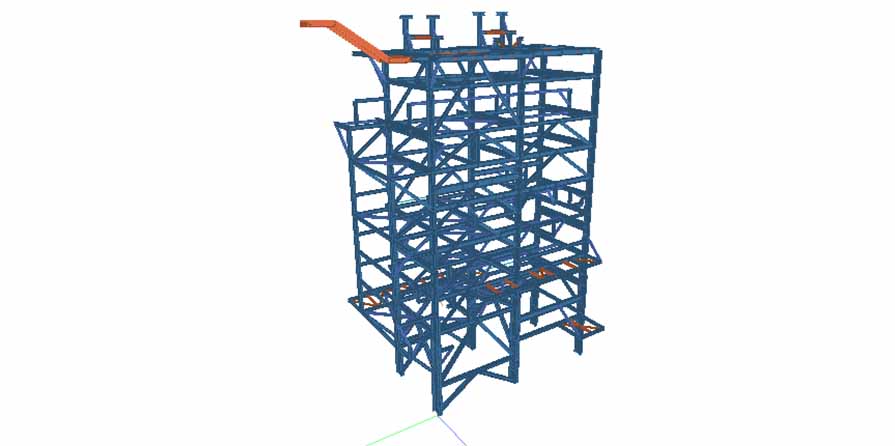

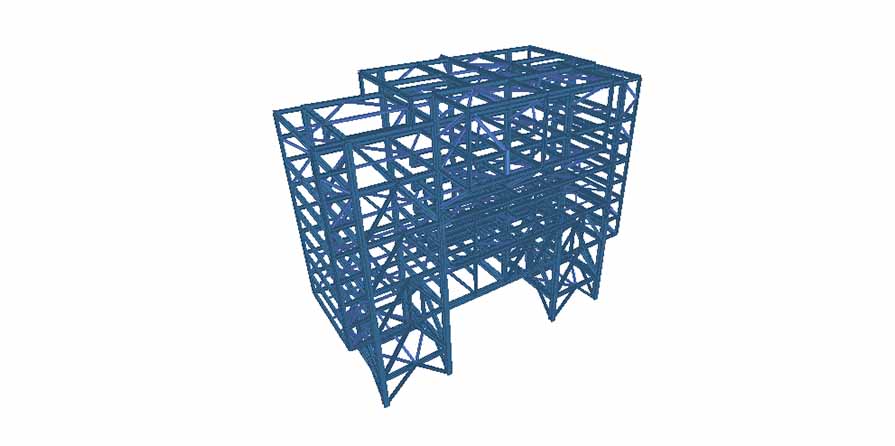

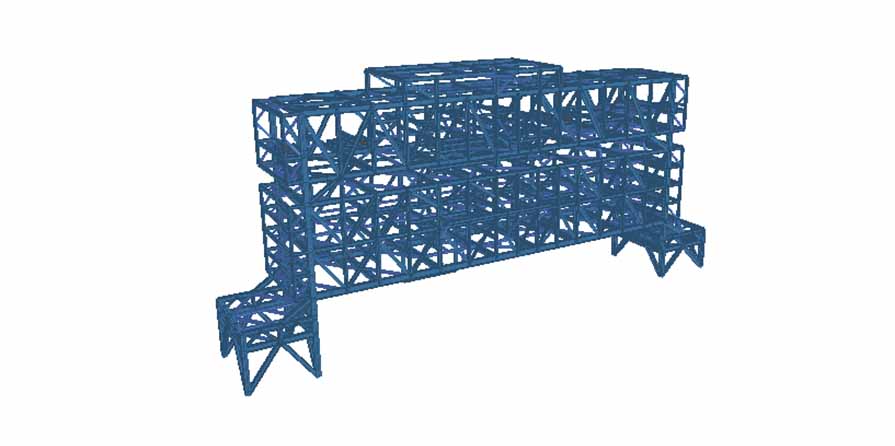

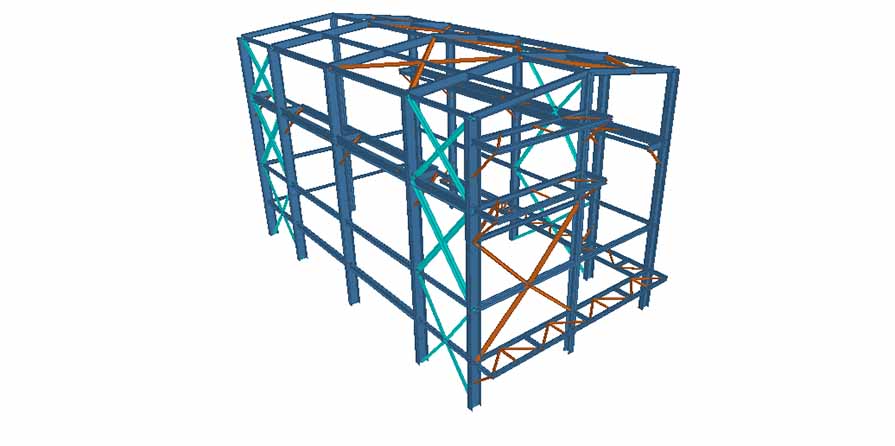

Project Images

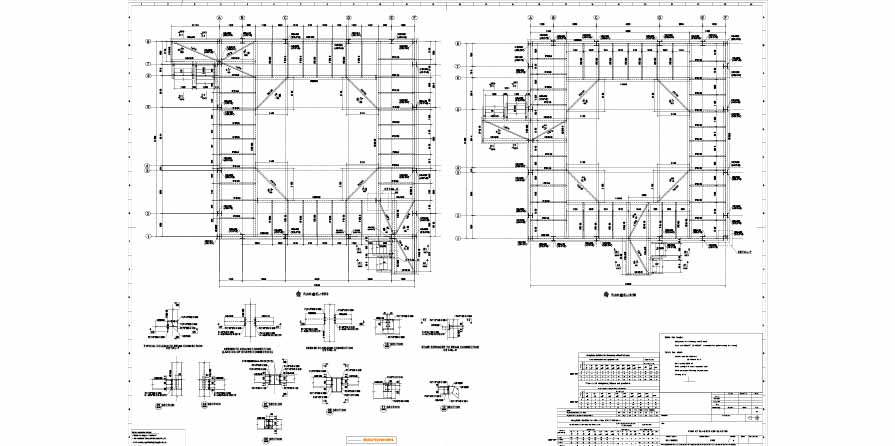

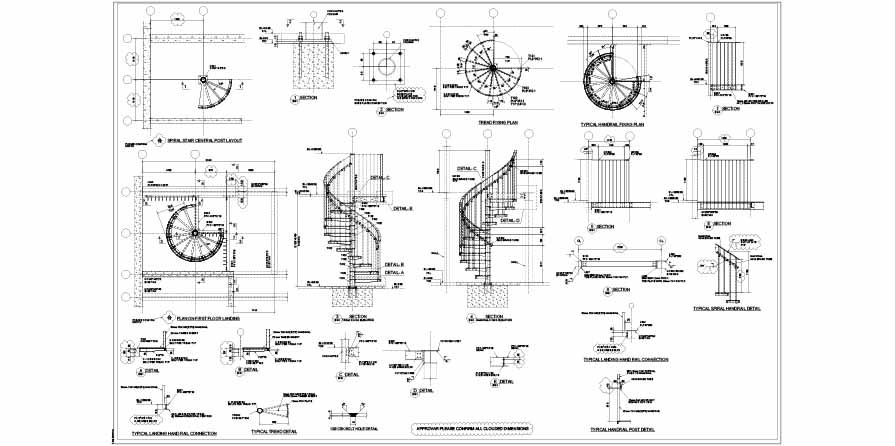

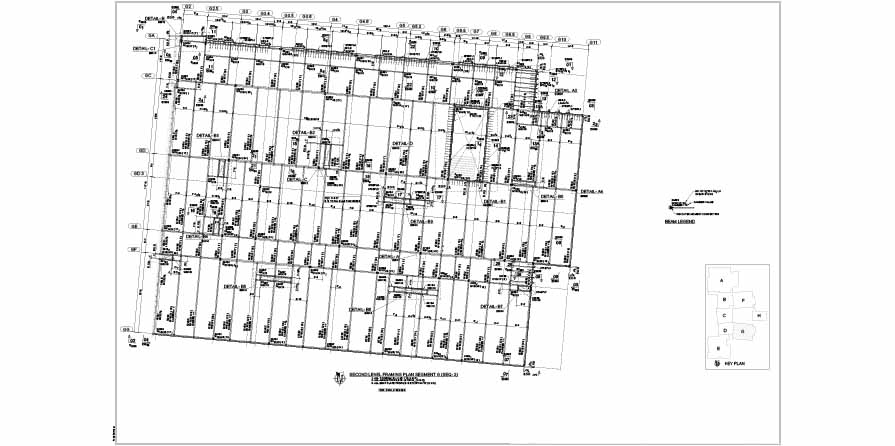

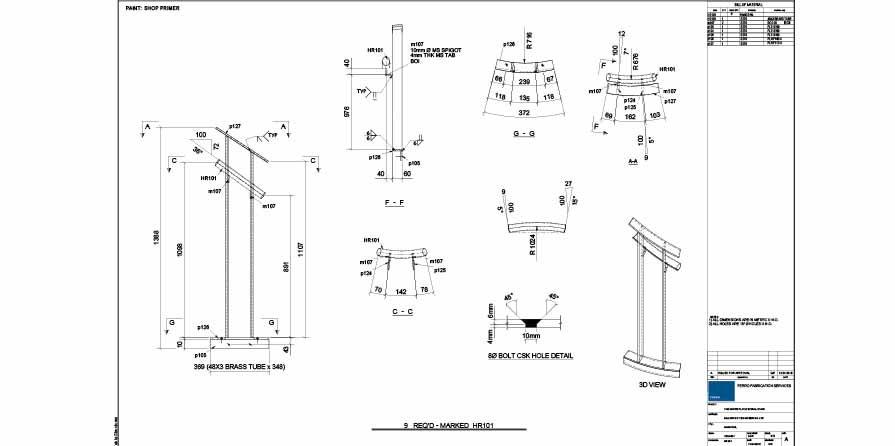

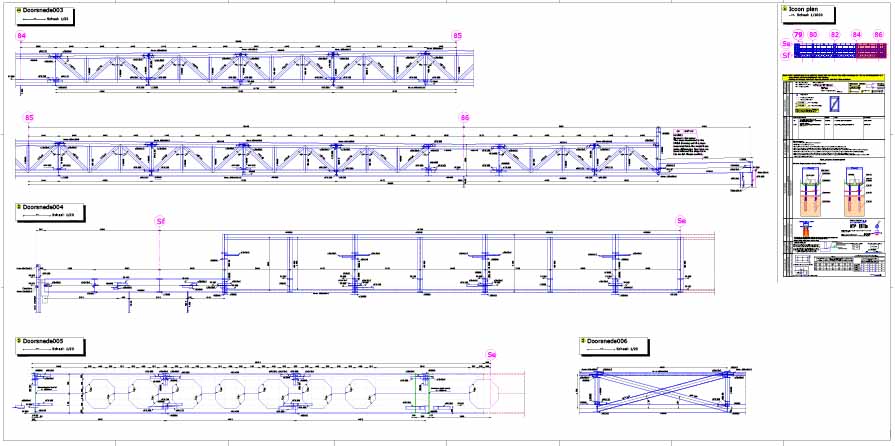

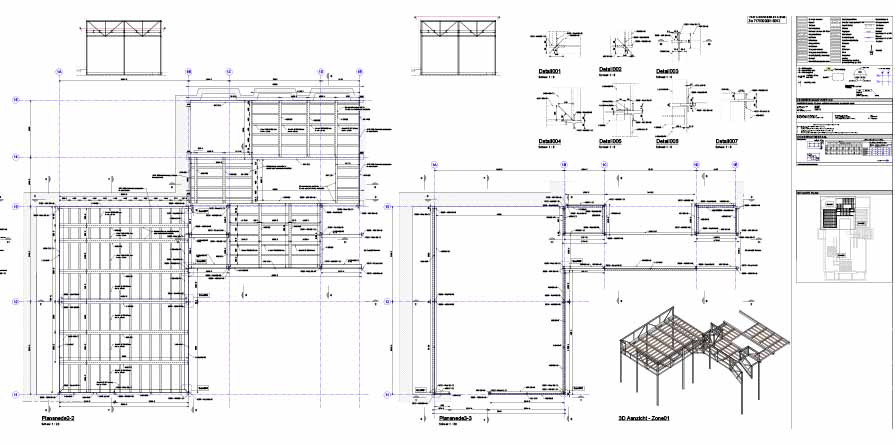

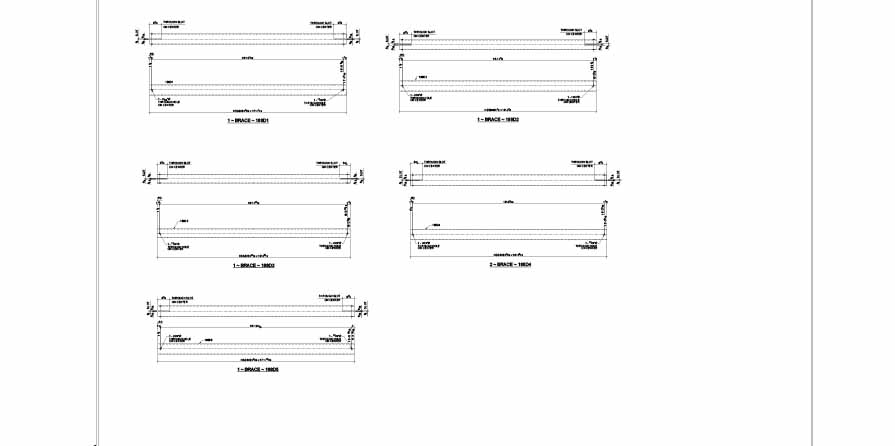

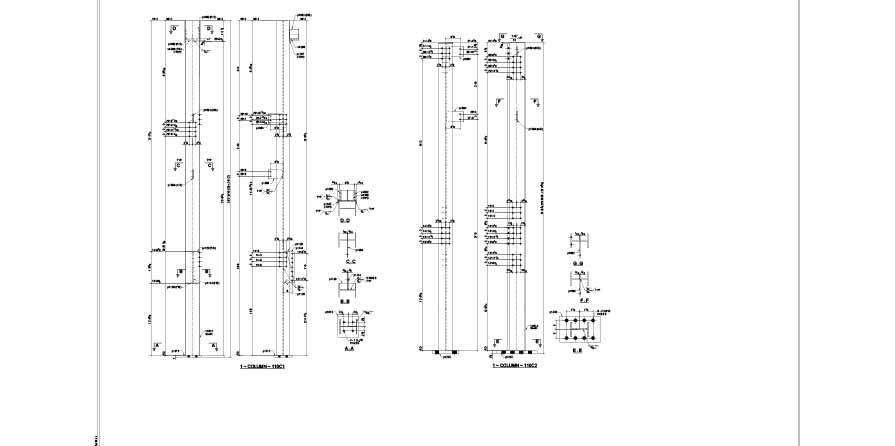

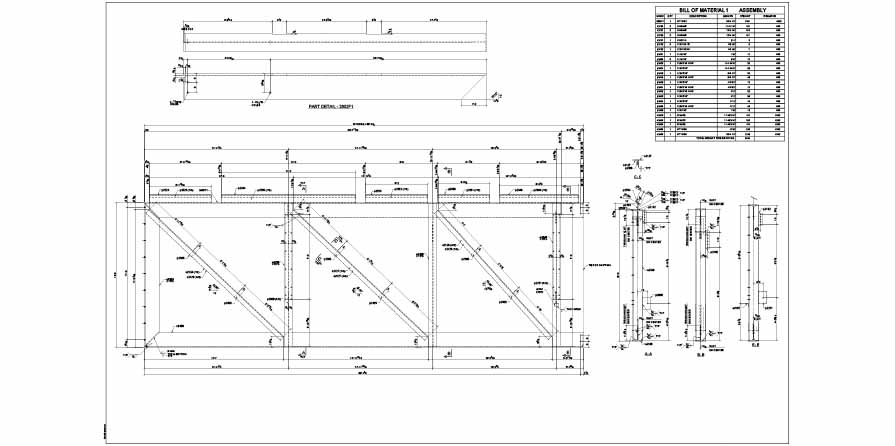

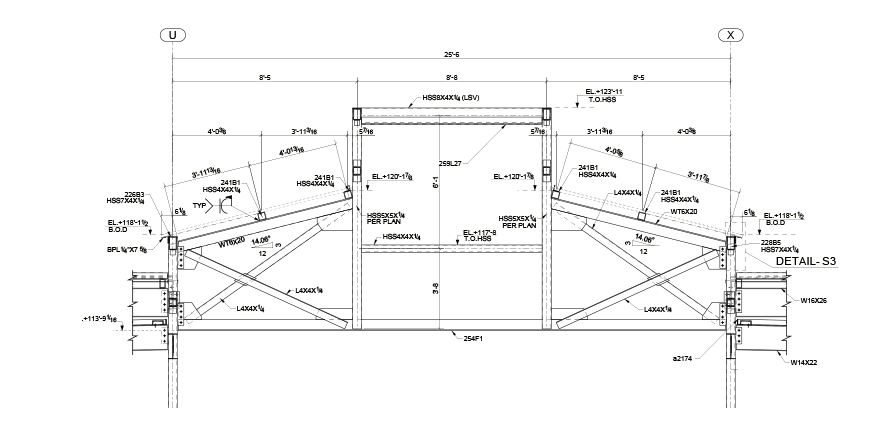

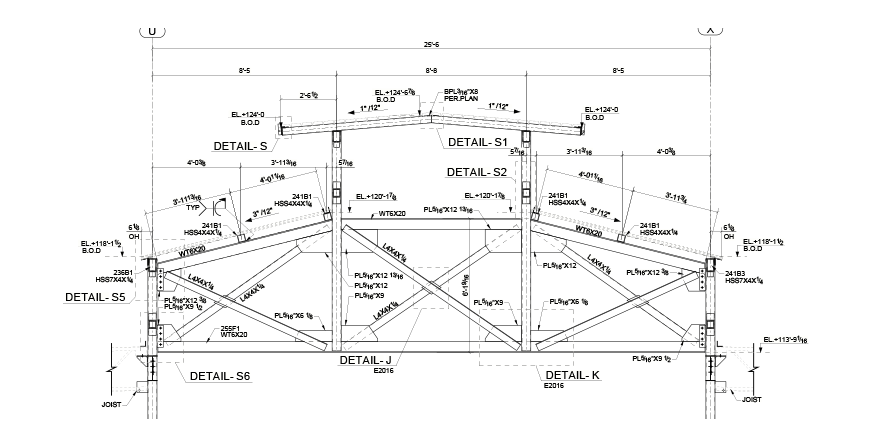

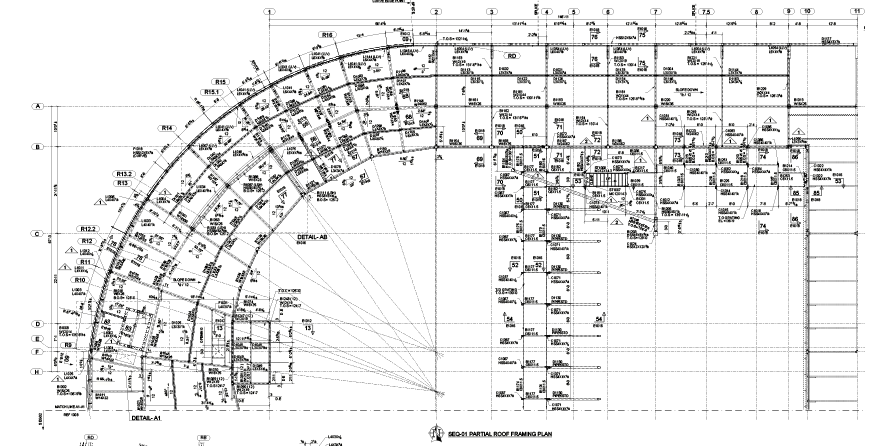

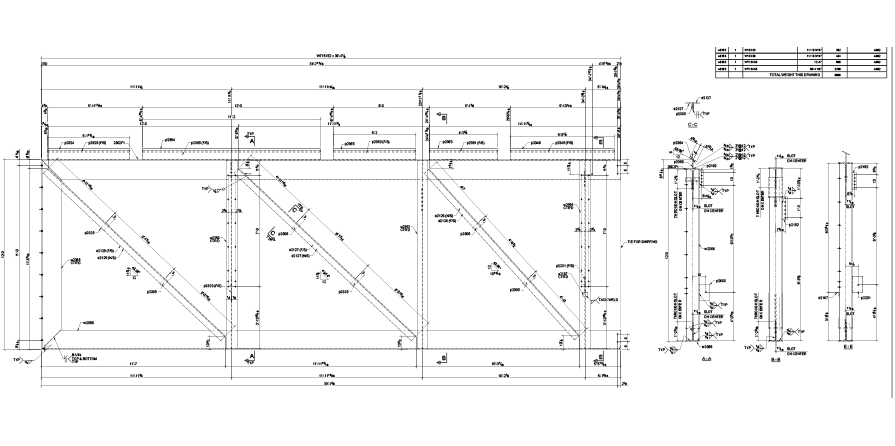

Sample Drawings

- Commercial or public buildings including churches, schools etc

- Offices

- Conference/event/assembly centers

- Medical facilities

- Residential buildings

- Tunnel galleries, platforms

- Renovation and extension work

- Buildings

- Warehouses

- Pipe racks, conveyors, hangers

- Technological structures

- Refinery structures

- Shelters

- Piperack-Pipe bridges

- Technological structure

- Grade mounted platforms

- Vessel mounted platforms

- Pipe supports

- Trestles

- Sleepers

- Skids and modules

- Miscellaneous structures